linear actuator

Introduction

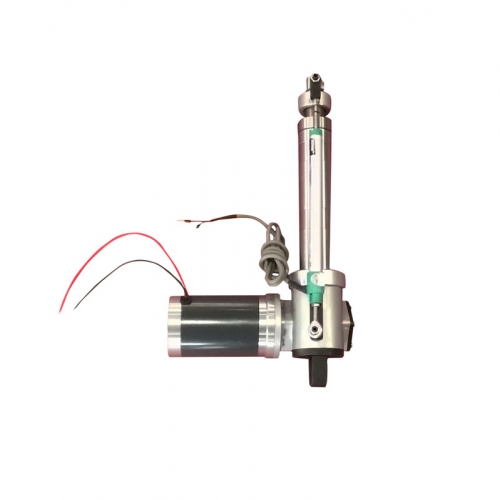

The Linear Actuator is an electric drive device that converts the rotary motion of the motor into a linear reciprocating motion of the push rod.It can be used in a variety of simple or complex processes as a mechanical machine for remote control, centralized control or automatic control.

Classification

1, according to the form of screw: trapezoidal screw type, ball screw type, planetary ball screw type.

2. According to motor type: DC motor type (12/24/36v), AC motor type (220/380v), stepper motor type, servo motor type, etc.

Main purpose

Electric medical bed, electric sofa, electric stand lifting rod, industrial electric lifting system, camera frame, head camera, wedding system

Main structure

The Linear Actuator is composed of a drive motor, a reduction gear, a screw, a nut, a guide bush, a push rod, a slide seat, a spring, a casing and a turbine, and a micro-motion control switch.

The Linear Actuator is a new type of electric actuator. The Linear Actuator is mainly composed of a motor, a push rod and a control device. It is a new type of linear actuator that can realize remote control and centralized control.The Linear Actuator makes a round-trip motion within a certain range of strokes. The standard stroke of the general Linear Actuator is 100, 150, 200, 250, 300, 350, 400mm. The special stroke can also be customized according to different application conditions.The Linear Actuator can be designed with different thrust Linear Actuators according to different application loads. Generally, the maximum thrust can reach 6000N, the no-load running speed is 4mm~35mm/s, and the Linear Actuator is powered by 24V/12V DC permanent magnet motor. The source converts the rotational motion of the motor into a linear reciprocating motion.Push a set of linkages to complete the switching of dampers, valves, gates, baffles, etc.The use of an Linear Actuator as an actuator not only reduces the air supply and auxiliary equipment required for pneumatic actuators, but also reduces the weight of the actuator.The pneumatic actuator needs a certain air pressure throughout the control operation. Although an amplifier with a small consumption can be used, the gas consumption is still huge.The Linear Actuator actuator adopts electric power when changing the control opening degree, and can no longer supply power when the required opening degree is reached. Therefore, from the viewpoint of energy saving, the Linear Actuator actuator has obvious energy saving advantages over the pneumatic actuator.It is suitable for long-distance operation and is widely used in the opening and closing, material handling, flow control, etc. of dampers, valves, gates and other institutions in the power, chemical, metallurgy, mining, light industry, transportation, ship and other departments.It has been used by more and more departments to replace the automatic devices of the mechanism hand, hydraulic valve and reduction transmission mechanism.

Working principle

After the motor is decelerated by the gear, a pair of screw nuts are driven.The rotary motion of the motor is changed into a linear motion, and the push rod is completed by the forward and reverse rotation of the motor.Complex movements such as turning and shaking can be accomplished by various levers, rockers or connecting rods.By changing the length of the lever arm, the stroke can be increased or increased.

Stroke control device

Turbine and worm drive form: the vortex on the motor gear drives the turbine to rotate, so that the small screw in the turbine moves axially. The connecting rod drives the limit rod to move axially. When the required stroke is reached, the limit is adjusted. When the block is pressed, the stroke switch is de-energized and the motor is stopped (the positive and negative controls are the same).

Gear transmission form: the motor drives the small screw rod installed on the inner tube through the reduction gear, and drives the axial running nut to be connected with it. When the set stroke is reached, the nut tentacles press the limit switch to disconnect the power supply. Stop motion (reverse is the same).

Optional potentiometer to display the stroke status of the putter, and can also be equipped with an encoder to achieve a complete stroke in a few steps (ie stop and go).

Characteristics

The design is novel and exquisite, small in size, high in precision, fully synchronized, self-locking performance, hygienic, direct drive of the motor, no need for pipeline air source, oil circuit, and now widely used in production lines, automobiles, ventilation windows, military, stage , textile, sewage treatment and other industries and equipment.

Optional accessories

1. Encoder: Accurately feedback the number of revolutions of the motor spindle by the number of pulses, so as to accurately calculate the stroke change of the Linear Actuator and achieve precise control.

2. Potentiometer: It is used to feedback the magnitude of the motor resistance, so as to reflect the stroke position where the push rod is located, and finally achieve the purpose of stopping the control push rod at any position in the middle of the stroke.

3. Hand-cranking device: Part of the worm gear structure and the gear structure of the push rod can be installed with the hand-cranked shaft. In the case of power failure, after the hand-wound wrench is connected, the push rod can be adjusted by the hand to adjust the position.

4. Hall feedback: The Hall circuit board is installed on the motor shaft, and the Hall principle can accurately feedback the number of motor rotations to achieve precise control of the push rod.

5, plc control: can provide plc access port, to achieve real-time control of the process.

6, controller: also known as transformer, is divided into control single, 2, 3 and more controllers.Turn the AC220V voltage into a DC12/24/36V voltage and connect the 1-n Linear Actuators in series with the operator.

7, the operator: also known as the hand controller, divided into functional single row, 2 rows, 3 rows and rows of operators.Connected to the controller.

The Linear Actuator is an electric drive device that converts the rotary motion of the motor into a linear reciprocating motion of the push rod.It can be used in a variety of simple or complex processes as a mechanical machine for remote control, centralized control or automatic control.

Classification

1, according to the form of screw: trapezoidal screw type, ball screw type, planetary ball screw type.

2. According to motor type: DC motor type (12/24/36v), AC motor type (220/380v), stepper motor type, servo motor type, etc.

Main purpose

Electric medical bed, electric sofa, electric stand lifting rod, industrial electric lifting system, camera frame, head camera, wedding system

Main structure

The Linear Actuator is composed of a drive motor, a reduction gear, a screw, a nut, a guide bush, a push rod, a slide seat, a spring, a casing and a turbine, and a micro-motion control switch.

The Linear Actuator is a new type of electric actuator. The Linear Actuator is mainly composed of a motor, a push rod and a control device. It is a new type of linear actuator that can realize remote control and centralized control.The Linear Actuator makes a round-trip motion within a certain range of strokes. The standard stroke of the general Linear Actuator is 100, 150, 200, 250, 300, 350, 400mm. The special stroke can also be customized according to different application conditions.The Linear Actuator can be designed with different thrust Linear Actuators according to different application loads. Generally, the maximum thrust can reach 6000N, the no-load running speed is 4mm~35mm/s, and the Linear Actuator is powered by 24V/12V DC permanent magnet motor. The source converts the rotational motion of the motor into a linear reciprocating motion.Push a set of linkages to complete the switching of dampers, valves, gates, baffles, etc.The use of an Linear Actuator as an actuator not only reduces the air supply and auxiliary equipment required for pneumatic actuators, but also reduces the weight of the actuator.The pneumatic actuator needs a certain air pressure throughout the control operation. Although an amplifier with a small consumption can be used, the gas consumption is still huge.The Linear Actuator actuator adopts electric power when changing the control opening degree, and can no longer supply power when the required opening degree is reached. Therefore, from the viewpoint of energy saving, the Linear Actuator actuator has obvious energy saving advantages over the pneumatic actuator.It is suitable for long-distance operation and is widely used in the opening and closing, material handling, flow control, etc. of dampers, valves, gates and other institutions in the power, chemical, metallurgy, mining, light industry, transportation, ship and other departments.It has been used by more and more departments to replace the automatic devices of the mechanism hand, hydraulic valve and reduction transmission mechanism.

Working principle

After the motor is decelerated by the gear, a pair of screw nuts are driven.The rotary motion of the motor is changed into a linear motion, and the push rod is completed by the forward and reverse rotation of the motor.Complex movements such as turning and shaking can be accomplished by various levers, rockers or connecting rods.By changing the length of the lever arm, the stroke can be increased or increased.

Stroke control device

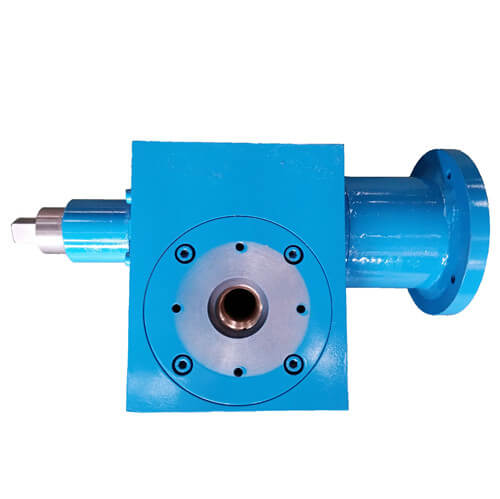

Turbine and worm drive form: the vortex on the motor gear drives the turbine to rotate, so that the small screw in the turbine moves axially. The connecting rod drives the limit rod to move axially. When the required stroke is reached, the limit is adjusted. When the block is pressed, the stroke switch is de-energized and the motor is stopped (the positive and negative controls are the same).

Gear transmission form: the motor drives the small screw rod installed on the inner tube through the reduction gear, and drives the axial running nut to be connected with it. When the set stroke is reached, the nut tentacles press the limit switch to disconnect the power supply. Stop motion (reverse is the same).

Optional potentiometer to display the stroke status of the putter, and can also be equipped with an encoder to achieve a complete stroke in a few steps (ie stop and go).

Characteristics

The design is novel and exquisite, small in size, high in precision, fully synchronized, self-locking performance, hygienic, direct drive of the motor, no need for pipeline air source, oil circuit, and now widely used in production lines, automobiles, ventilation windows, military, stage , textile, sewage treatment and other industries and equipment.

Optional accessories

1. Encoder: Accurately feedback the number of revolutions of the motor spindle by the number of pulses, so as to accurately calculate the stroke change of the Linear Actuator and achieve precise control.

2. Potentiometer: It is used to feedback the magnitude of the motor resistance, so as to reflect the stroke position where the push rod is located, and finally achieve the purpose of stopping the control push rod at any position in the middle of the stroke.

3. Hand-cranking device: Part of the worm gear structure and the gear structure of the push rod can be installed with the hand-cranked shaft. In the case of power failure, after the hand-wound wrench is connected, the push rod can be adjusted by the hand to adjust the position.

4. Hall feedback: The Hall circuit board is installed on the motor shaft, and the Hall principle can accurately feedback the number of motor rotations to achieve precise control of the push rod.

5, plc control: can provide plc access port, to achieve real-time control of the process.

6, controller: also known as transformer, is divided into control single, 2, 3 and more controllers.Turn the AC220V voltage into a DC12/24/36V voltage and connect the 1-n Linear Actuators in series with the operator.

7, the operator: also known as the hand controller, divided into functional single row, 2 rows, 3 rows and rows of operators.Connected to the controller.

Products

1

Hot Products